Lost Wax Casting Manufacturer

Hengke Metal has more than 1,200 clients from all over the world, over 40% of the world’s leading global brands, For aerospace, military, industry, etc. Hengke Metal is committed to researching and developing Lost Wax Casting, and our goal is to provide the best Lost Wax Castings to our clients. Buy online your Lost Wax Casting at Hengke Metal for optimized traceability.

All Lost Wax Castings Are In-Stock and Fastest Delivery

Our factory produces a large number of high-quality investment castings that meet the requirements of different markets. All castigns can be made with your drawing, and welcome to OEM and private label service is available. Contact us get the latest catalog and price list today.

Frequently Asked Questions

Lost Wax Casting Company: Preserving Artistry Through Precision

Lost wax casting, also known as investment casting, is an ancient and intricate method of creating metal sculptures, jewelry, and industrial components. This age-old technique has found a modern home in the form of specialized Lost Wax Casting Companies. These companies play a pivotal role in preserving artistry through precision and innovation.

The Artistic Heritage

Lost wax casting has a rich history dating back thousands of years to ancient civilizations like Mesopotamia, Egypt, and China. It was employed to craft intricate jewelry, religious artifacts, and sculptures. Many of these ancient masterpieces have survived the test of time, showcasing the longevity and beauty achievable through this method.

Today, Lost Wax Casting Companies are the torchbearers of this artistic heritage. They bridge the gap between tradition and modernity, employing advanced technology to preserve the artistry of the past.

The Process

The lost wax casting process is a complex yet fascinating one. Here’s a simplified overview:

- Sculpting: The process begins with an artisan creating a detailed model of the desired object. This can be made from various materials, including clay or wax. This initial sculpture is often the most artistic phase of the process.

- Mold Creation: A mold is created around the original sculpture. This mold can be made from rubber or silicone, capturing every intricate detail.

- Wax Replication: Once the mold is set, it’s filled with molten wax. After the wax cools and solidifies, it’s carefully removed, leaving behind a wax replica of the original sculpture.

- Assembly: The wax replicas, also known as “patterns,” are assembled onto a wax tree. This tree will eventually be encased in a ceramic shell.

- Ceramic Shell: The wax tree is dipped multiple times into a slurry of ceramic material. Each layer is allowed to dry before the next dip. This creates a strong and heat-resistant shell around the wax.

- Burnout: The ceramic shell is heated in a kiln, causing the wax to melt and drain out. This leaves a cavity inside the ceramic shell that perfectly mirrors the original sculpture.

- Metal Pouring: Molten metal, often bronze or silver, is poured into the ceramic shell. The metal fills the cavity, taking the shape of the original sculpture.

- Cooling and Finishing: After the metal cools and solidifies, the ceramic shell is broken away, revealing the metal object inside. This rough casting is then polished and finished to achieve the desired appearance.

The Role of Lost Wax Casting Companies

Lost Wax Casting Companies are the guardians of this intricate process. They serve various sectors, each with unique requirements:

- Art and Sculpture: Many artists and sculptors rely on Lost Wax Casting Companies to bring their visions to life. The precision and fidelity of this method ensure that the final piece accurately reflects the artist’s intent.

- Jewelry: Fine jewelry often incorporates intricate designs that can only be achieved through lost wax casting. Companies in this sector create exquisite pieces, from delicate rings to ornate necklaces.

- Industrial Components: Lost wax casting is used in industries such as aerospace, automotive, and engineering to create precise, durable metal components. Its ability to produce complex shapes with tight tolerances is invaluable in these sectors.

- Dentistry: Dentists use lost wax casting to create accurate dental prostheses, crowns, and bridges. The biocompatibility of certain metals ensures they are safe for use in the human body.

The Future of Lost Wax Casting

The future of lost wax casting is promising, thanks to technological advancements. Computer-aided design (CAD) and 3D printing have streamlined the initial sculpting process, making it more accessible and efficient. Additionally, materials science has led to the development of new alloys that enhance the properties of cast metals.

In conclusion, Lost Wax Casting Companies are the modern custodians of an ancient and artistic technique. They combine tradition, artistry, and technology to create intricate metal objects with precision and beauty. As long as there is a demand for finely crafted sculptures, jewelry, and industrial components, these companies will continue to thrive, preserving the legacy of lost wax casting for generations to come.

Buying Lost Wax Castings from Chinese Manufacturers

China has become a major player in the global manufacturing industry, offering a wide range of products and services. Among these are lost wax castings, a process that requires precision, expertise, and craftsmanship. Here, we explore why individuals and businesses might consider buying lost wax castings from Chinese manufacturers.

1. Cost-Effective Solutions

One of the primary reasons to source lost wax castings from China is cost-effectiveness. Chinese manufacturers often provide competitive pricing due to lower labor and production costs. This cost advantage can significantly benefit businesses looking to maximize their budget without compromising on quality.

2. Expertise in Lost Wax Casting

China has a long history of metalworking and casting techniques, including lost wax casting. Chinese manufacturers have honed their skills over generations, and today, many employ highly skilled artisans and engineers who are well-versed in this intricate art form. Their expertise ensures that you receive high-quality castings.

3. State-of-the-Art Facilities

China has made substantial investments in modern manufacturing facilities and technology. Chinese foundries are equipped with state-of-the-art machinery, including CNC (Computer Numerical Control) machines and 3D printing technology, which can enhance the precision and efficiency of the lost wax casting process.

4. Versatility in Materials

Chinese manufacturers offer versatility in the choice of materials for lost wax castings. Whether you need castings in bronze, brass, aluminum, stainless steel, or other alloys, you can find a wide range of options to suit your specific requirements.

5. Customization and Design Support

Chinese manufacturers often have the capacity to handle customized projects. They can work closely with clients to bring their unique designs to life. Many offer design support, helping clients optimize their designs for the lost wax casting process.

6. Quality Control

Reputable Chinese manufacturers prioritize quality control measures to ensure that the castings meet international standards. They conduct rigorous inspections and testing at various stages of production to guarantee the integrity and functionality of the final product.

7. Fast Turnaround Times

China’s vast manufacturing infrastructure allows for faster production and shorter lead times. This is advantageous for businesses that require quick turnaround on their lost wax casting orders, helping them meet deadlines and stay competitive in their markets.

8. Scalability

Chinese manufacturers can typically handle both small-scale and large-scale production runs. Whether you need a single prototype or a large batch of castings, they have the capacity to accommodate your production needs.

9. Global Shipping Capabilities

China’s well-developed logistics networks ensure efficient and cost-effective shipping to destinations worldwide. This is especially important for businesses that require international distribution of their products.

10. Regulatory Compliance

Many Chinese manufacturers adhere to international quality and safety standards. They are often certified and follow environmental regulations, ensuring that their manufacturing processes are in compliance with global norms.

However, it’s crucial to exercise due diligence when selecting a Chinese manufacturer for lost wax castings. Research their reputation, ask for references, and request samples before committing to a partnership. Additionally, consider cultural and language differences, as effective communication is key to a successful collaboration.

In conclusion, sourcing lost wax castings from Chinese manufacturers offers a host of advantages, including cost-effectiveness, expertise, modern facilities, and a wide range of materials. With careful selection and collaboration, businesses and individuals can tap into China’s manufacturing prowess to fulfill their lost wax casting needs while enjoying the benefits of a global supply chain.

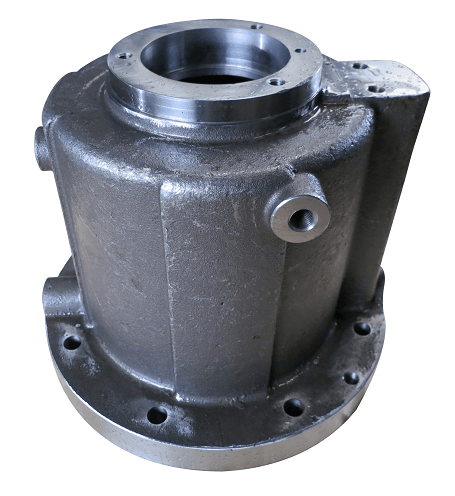

Sourcing Lost Wax Casting Pump and Valve Parts from Chinese Manufacturers

Sourcing Lost Wax Casting Pump and Valve Parts from Chinese Company

China’s manufacturing prowess has made it a go-to destination for a wide range of industrial components, including lost wax casting pump and valve parts. These critical components are integral to various industries, and sourcing them from Chinese manufacturers offers several advantages.

1. Expertise in Precision Casting

Chinese manufacturers have a long history of metalworking and precision casting, making them well-suited to produce intricate parts like pump and valve components using the lost wax casting method. This expertise ensures that you receive parts with precise dimensions and high-quality finishes.

2. Cost-Effective Solutions

Cost-effectiveness is one of the primary reasons businesses turn to Chinese manufacturers. Lower labor and production costs often translate to competitive pricing for pump and valve casting parts, making it an attractive option for cost-conscious buyers.

3. Quality Control

Reputable Chinese manufacturers prioritize quality control throughout the production process. They typically employ stringent inspection and testing procedures to ensure that the castings meet international standards. This commitment to quality provides peace of mind to buyers concerned about the reliability and durability of the components.

4. Material Selection

Chinese manufacturers offer a wide range of materials for lost wax casting, allowing buyers to choose the most suitable alloy for their specific application. Whether you require parts made from stainless steel, brass, bronze, or other materials, you can find options that align with your needs.

5. Customization and Design Support

Many Chinese manufacturers are equipped to handle customized projects. They can collaborate with clients to bring their unique designs to life. Additionally, they often offer design support, helping clients optimize their designs for the lost wax casting process to enhance efficiency and functionality.

6. State-of-the-Art Facilities

China’s manufacturing sector has made substantial investments in modern facilities and technology. Chinese foundries are equipped with advanced machinery, including CNC machines and 3D printing technology, which can improve the precision and efficiency of the lost wax casting process.

7. Scalability

Chinese manufacturers are capable of handling both small-scale and large-scale production runs. Whether you need a limited quantity of specialized components or require a large batch of standardized parts, they can accommodate your production needs.

8. Fast Turnaround Times

China’s vast manufacturing infrastructure allows for faster production and shorter lead times. This is particularly advantageous for businesses that need to meet tight production schedules and deadlines.

9. Global Shipping Capabilities

China boasts a well-developed logistics network that facilitates efficient and cost-effective shipping to destinations worldwide. This is essential for businesses requiring international distribution of their products.

10. Regulatory Compliance

Many Chinese manufacturers adhere to international quality and safety standards. They often hold certifications and follow environmental regulations, ensuring that their manufacturing processes align with global norms.

When considering sourcing pump and valve casting parts from Chinese manufacturers, it’s crucial to conduct thorough due diligence. Research the manufacturer’s reputation, request references, and ask for samples to evaluate the quality of their work. Additionally, consider factors such as communication, language, and cultural differences to ensure effective collaboration.

In conclusion, sourcing lost wax casting pump and valve parts from Chinese manufacturers offers numerous advantages, including cost-effectiveness, expertise, quality control, material options, customization capabilities, and fast turnaround times. By carefully selecting a trusted manufacturing partner, businesses can benefit from China’s manufacturing capabilities while ensuring the reliability and performance of critical components in their operations.

Precision Metal Castings from a Leading Lost Wax Foundry

Precision Metal Castings from a Leading Lost Wax Foundry

Lost wax casting, also known as investment casting, is a specialized metal forming process used to create complex, high-performance cast components across diverse industries. This article provides an overview of lost wax casting and its capabilities for producing precision metal castings. We’ll explore the lost wax process, alloys, applications, quality considerations, and benefits that make investment casting a go-to choice for critical cast components.

What Is Lost Wax Casting?

Lost wax casting is an advanced metal casting technique used to fabricate near-net shape metal parts with exceptional precision, surface finish, and dimensional accuracy. It begins by creating a wax pattern of the final part geometry. This wax pattern is surrounded by a ceramic shell mold and the wax is melted out (“lost”) to leave a hollow space. Molten metal is then poured into the mold to form the casting. The shell is removed after the metal solidifies. Lost wax casting enables complex internal features like threads and channels that would be difficult or impossible with other processes. It is ideal for lower volume production runs and prototype parts.

Key Metals Cast with the Lost Wax Process

Lost wax casting excels at producing castings from high-performance alloys including:

- Stainless Steel – Corrosion-resistant stainless steel alloys including 304 and 316 are commonly used for lost wax castings across many industries.

- Aluminum – Lightweight aluminum alloys like A356 and 319 are cast for automotive and aerospace applications.

- Titanium – Strong but lightweight titanium alloys are ideal for implants, aerospace components, and other critical structures.

- Nickel Alloys – Superalloys including Inconel, Monel, and Hastelloy offer high strength and heat resistance.

- Cobalt Chrome – Cobalt chrome has excellent biocompatibility and wear resistance, making it popular for orthopedic and dental prosthetics.

Industry Applications of Lost Wax Cast Parts

Investment castings produced via the lost wax process provide optimized performance in:

- Aerospace – Turbine blades, airfoil vanes, frames, engine components, and spacecraft parts.

- Medical – Joint replacement implants, surgical tools, bone fixation devices, and dental prosthetics.

- Defense – Castings for ordnance, armor, and other military applications where reliability is critical.

- Energy – Valves, pumps, drilling tools, and other components used in demanding oil, gas, and industrial environments.

- Automotive – Turbocharger housings, manifolds, clamps, connectors, and precision fit drivetrain parts.

Lost Wax Casting for Prototypes and Low Volume Production

In addition to production runs, lost wax casting is ideal for rapid prototyping of new designs. A 3D printed plastic or wax model of the part can be directly cast in metal, providing functional prototypes for design verification and testing. Short lead times for wax patterns also support low volume or pilot production. When design is finalized, the casting process enables smooth transition to higher volume manufacturing.

Achieving Precision Tolerances with Lost Wax Castings

Lost wax manufacturing processes are optimized to achieve precision tolerances down to +/- 0.005 inches or better. Tight process controls, specialized tooling, rigorous inspection, and advanced metrology maintain dimensions and reproducibility. Multi-axis CNC machining of castings can hold extremely tight tolerances on critical features. These capabilities make lost wax casting suitable for complex castings used in highly regulated industries like aerospace, defense, and medical.

Superior Casting Quality and Consistency

Leading investment casting foundries have extensive quality assurance systems in place. Lost wax castings meet stringent requirements of Nadcap, ISO, and industry body specifications. Defect detection techniques include X-ray, computed tomography, magnetic particle, and dye penetrant inspection. Robust process controls, validated procedures, certified technicians, raw material testing, and statistical control ensure repeatable casting quality. Matching or exceeding OEM specifications is a given.

Design Freedom for Complex, Monolithic Cast Parts

The lost wax casting process facilitates complex geometries like internal channels, undercuts, and hollow sections that cannot be produced by other metal forming methods. Multi-part assemblies can be consolidated into integrated, monolithic castings to optimize performance while minimizing assembly operations. Modern casting simulation software models thermal gradients, solidification, residual stresses and other parameters to engineer castability into the part design. This design freedom unlocks performance improvements otherwise unattainable.

Superior Finish of Lost Wax Cast Surfaces

The ceramic shell mold created during investment casting delivers extremely precise surface finishes and detail resolution. Fine features are replicated with high fidelity. Textures and identifying marks can be incorporated at the design stage. Minimal secondary finishing operations are required after casting and machining. The as-cast surface quality surpasses sand and permanent mold casting processes, providing insider performance advantages.

Design Optimization for Weight and Material Reduction

Lost wax casting enables lightweight, slim-wall designs not feasible with forging or machining from bar stock. Thin cross-sections down to 0.020 – 0.035 inches minimize weight while retaining strength. Detailed thermal modeling helps avoid unsoundness defects during casting by identifying areas prone to porosity. Hollow cores remove unnecessary mass. Alloy substitutions further optimize weight goals. Reduced machining and materials savings provide a lower cost solution.

In summary, lost wax or investment casting provides unmatched design freedom, surface quality, dimensional accuracy, and consistency for metal castings used in the most demanding applications across diverse markets. Leading lost wax foundries continue advancing the technology through rigorous quality protocols, vertically integrated operations, advanced inspection techniques, and control of the entire casting production workflow. Lost wax casting delivers high-performance castings unavailable through other manufacturing methods.

More FAQs on Lost Wax Casting Company

Frequently Asked Questions

What is lost wax casting?

Lost wax casting, also called investment casting, is a metal forming process where a wax pattern is surrounded by a ceramic mold and the wax is melted out to leave a hollow space for molten metal to be poured into.

What industries use lost wax casting?

Key industries utilizing lost wax castings include aerospace, defense, medical, energy, and other industrial segments.

What materials can be cast with lost wax casting?

Common alloys cast include stainless steel, aluminum, titanium, nickel alloys, cobalt chrome, and exotics like Inconel or Hastelloy.

What are some key innovations in lost wax casting?

Innovations include new alloys, increased automation, simulations, rapid prototyping, big data analytics, sustainability initiatives, and highly customized castings.

Who are leading lost wax casting manufacturers?

Top suppliers include Signicast, Ross Group, CIREX Foundry, Arconic, PCC Structurals, Tech Cast, Merrick Industries, Parallax, Ferralloy, and Castings Technology International.

What future advancements could shape lost wax casting?

Potential future innovations include novel alloys, increased automation, integrated design software, nanomaterials, large monolithic casts, rapid tooling, and real-time monitoring with IoT sensors.

How does lost wax casting produce complex shapes?

The wax pattern can be injection molded into highly complex, precise shapes before the metal is cast into the same form.

Why is lost wax preferred for some applications?

Lost wax can produce near-net shape castings with excellent surface finish, dimensional accuracy, and complex inner features not possible with other methods.

How does lost wax casting ensure high quality?

Extensive process controls, quality programs, advanced inspection methods, automation, and vertically integrated operations enable casting excellence.

What finishing operations may be required after casting?

Castings often require additional heat treating, machining, coating, testing and other secondary operations to achieve the final part configuration.

The Lost Wax Casting Industry: Leading Manufacturers and Innovations

The Lost Wax Casting Industry: Leading Manufacturers and Innovations

Lost wax casting, also known as investment casting, is a metal forming process with origins dating back thousands of years. It remains an essential manufacturing technique for producing complex, high-precision metal components across diverse industries. In lost wax casting, a mold is formed around a wax pattern which is then melted, or “lost”, to create a hollow mold space for molten metal to fill. Manufacturers specializing in lost wax casting have innovated over decades to refine the process and expand its capabilities. We will explore the competitive landscape of lost wax casting suppliers as well as emerging trends shaping the industry.

Signicast Corporation

Signicast is one of the oldest and largest lost wax casting suppliers in North America with over 70 years of experience. Headquartered in Milwaukee, Wisconsin, Signicast provides lost wax casting and machining for original equipment manufacturers (OEMs) in the aerospace, defense, medical, and other industries. The company operates multiple facilities with advanced foundry capabilities in the U.S. Signicast specializes in complex, close-tolerance castings and can work with over 170 metal alloys including stainless steel, aluminum, nickel, and cobalt-based alloys. With in-house tooling, wax pattern production, casting, heat treating, and finishing, Signicast serves as a one-stop shop.

Ross Group Inc.

Ross Group is a full-service casting house focused primarily on stainless steel and nickel alloy lost wax investment castings. Located in Midland, Texas, Ross Group provides casting and machining for oil and gas, naval marine, power generation, and other industrial applications. The company’s in-house capabilities include tooling design and manufacture, wax pattern injection, ceramic shell building, autoclave processes, metal pouring, testing, machining, and finishing. This vertical integration allows Ross Group to control all aspects of the casting process while meeting stringent quality standards.

CIREX Foundry Group

Headquartered in Wisconsin with two U.S. lost wax casting facilities, CIREX Foundry Group manufactures complex castings for defense, aerospace, medical, fluid handling, and other industries. CIREX offers casting capabilities in stainless steel, nickel, cobalt, and titanium alloys as well as reactive and refractory metals. The company emphasizes quality and process control, with all foundries ISO 9001 and AS9100 certified. CIREX combines extensive casting experience with investments in robotics, automation, and technology integration to drive innovation. This includes developing new alloys and casting techniques to push the limits of size, precision, and complexity.

Arconic Corporation

Arconic is a leading provider of nickel, cobalt, titanium and aluminum castings through lost wax investment casting. After being spun off from parent company Alcoa, Arconic now operates as an independent company while retaining over 50 years of metal casting expertise. Arconic produces airfoil castings for aircraft engines, frames for aerospace structures, and blades for industrial gas turbines. The company operates advanced foundries and process development centers across the United States and Europe to serve aerospace, power generation, commercial transportation, and general industrial markets.

PCC Structurals, Inc.

PCC Structurals is a Portland, Oregon based investment casting supplier focused on structural investment castings in both titanium and nickel alloy. The company produces critical rotating and static components for commercial and military aerospace as well as land-based turbine applications. PCC Structurals operates a 150,000 square foot foundry in Portland along with structural casting facilities in Los Angeles and Wichita. As a subsidiary of Precision Castparts Corp., PCC Structurals manufactures castings under tight quality control for extreme environments. PCC’s capabilities include full machining, testing, and processing services.

Tech Cast Inc.

Tech Cast is a lost wax casting house started in 1969 and located in Lynchburg, Virginia. The company manufactures stainless steel, nickel alloy, cobalt chrome, and titanium castings for the medical, aerospace, power generation, and defense industries. With in-house foundry and machining capabilities, Tech Cast produces castings under 150 pounds for biomedical implants to 1,500 pounds for aerospace hydraulic manifolds. The company is AS9100 and ISO 13485 certified and can provide ancillary services like passivation, testing, heat treatment, assembly, and packaging. Tech Cast works with customers on casting design to optimize performance and manufacturability.

Merrick Industries Inc.

Merrick Industries, headquartered in Cleveland, Ohio, is a precision investment caster of titanium, nickel, cobalt chrome, and aluminum castings for aerospace, power generation, and other industries. Merrick combines casting expertise with engineering and metallurgy capabilities to transform designs into finished cast components. The company operates one large foundry in Ohio along with machining centers and plating facilities. Merrick emphasizes quality, traceability, and continuous improvement, with AS9100 and Nadcap accreditation. Merrick’s capabilities include cast airfoils over 100 inches long and fully machined castings weighing thousands of pounds.

Parallax Inc.

Parallax is a full-service investment casting supplier founded in 1970 and located in Santa Ana, California. The company specializes in quick turn prototype and low volume casting production for aerospace, defense, maritime, medical, and other industries. Parallax manufactures small, highly complex castings utilizing 3D printed wax patterns and specialized ceramic slurry processes. Casting alloys include titanium, stainless steel, aluminum, Inconel, cobalt chrome, and other exotics. Parallax also provides in-house machining, polishing, passivation, testing, and other finishing services.

Ferralloy Inc.

Ferralloy is a St. Louis based producer of highly complex and multi-alloy investment steel castings. The company manufactures castings up to 1,500 pounds for the military, aerospace, chemical processing, and mining industries. Ferralloy’s steel casting capabilities include carbon, alloy, stainless, and duplex stainless steels along with wear-resistant alloys. Ferralloy operates a 200,000 square foot foundry with two electric arc furnaces and three AOD vessels for melting and refining. Automated casting, inspection, finishing and testing enables high quality and control standards. Ferralloy also provides in-house heat treating and machining.

Castings Technology International

Castings Technology International (CTI) offers full-service investment casting across a variety of alloys including aluminum, titanium, stainless steel, and nickel-based super alloys. CTI operates six foundry facilities in the Midwestern United States that produce precision castings for aerospace, defense, medical, and other industries. The company has expertise in complex, multi-alloy castings used in rotating turbo machinery as well as large static components. CTI also provides secondary operations like heat treating, machining, and coatings needed to deliver finished castings. Quality certifications include ISO 9001, AS9100, and Nadcap.

Key Trends in the Lost Wax Casting Industry

The lost wax casting industry has experienced significant changes in recent decades. Some of the major trends include:

- Improved Alloys – Development of higher-strength, more durable alloys enables production of thinner, lighter castings that can withstand extreme stresses and wear. Superalloys extend capabilities.

- Increased Automation – Robotics, conveyor systems and automated inspection allow foundries to improve reliability and repeatability while reducing costs.

- Simulations – Flow and thermal simulation software helps predict potential defects and optimize gating designs. Digital radiography and 3D computed tomography scans assess casting soundness.

- Rapid Prototyping – 3D printing accelerates prototype production using printed wax patterns and specialized rapid tooling. This reduces development timelines.

- Big Data Analytics – Extensive process data combined with predictive analytics and artificial intelligence improves quality control and forecasting.

- Sustainability – Foundries implement initiatives to reduce waste, energy and water use such as recycling, stormwater management, and renewable energy.

- Customized Castings – Custom alloys, textures, engineered surfaces and embedded sensors or controls provide unique cast performance capabilities.

The Future of Lost Wax Casting

Lost wax casting will continue advancing as a critical metal forming process. Here are some potential innovations that could shape the future:

- – Novel alloys with enhanced physical, mechanical and corrosion-resistant properties will expand applications for castings, including at extreme temperatures.

- – Automation, robotics and digital process monitoring will optimize all casting steps for maximum productivity and minimal defects.

- – Design software will integrate casting simulations into the design phase to engineer castability and required properties from the start.

- – Nanomaterials and engineered surfaces will deliver tailored functionality like self-lubrication, abrasion resistance and tunable energy absorption.

- – Joining technologies such as arc and friction welding of cast segments will enable larger, more complex monolithic castings.

- – Rapid tooling using additive manufacturing methods will accelerate prototype development and low volume production.

- – Internet of Things sensors will provide real-time monitoring of casts in service to predict failures and schedule maintenance.

- – Foundries will leverage big data and analytical tools to refine processes and quality control while identifying new innovation opportunities.

Lost wax casting has evolved from an ancient art into a high-tech manufacturing process. Leading foundries have developed extensive capabilities for casting complex, high-performance alloy components with maximum precision and reliability. Ongoing metals research combined with digital design tools, automation, and data analytics will support the next generation of innovations in lost wax casting. The industry’s top suppliers are well positioned to apply emerging technologies and deliver sophisticated casting solutions to their customers.

Let's Start A Project Together Today

Your Best Lost Wax Castings Supplier.

For the past many years, Hengke Metal specialized in producing all kinds of Lost Wax Castings, investment castings, marine hardware, valve parts casting, pump castings parts, food machinery casting parts, automotive castings parts, stainless steel investment casting, etc.

Contact Info

- Main Office Location:

Casting Industry Zone, Dongying City, Shandong China 523936 - Mail:

hengkecasting@gmail.com